What Advantages Does Aerodynamic Grain Drying Technology Provide?

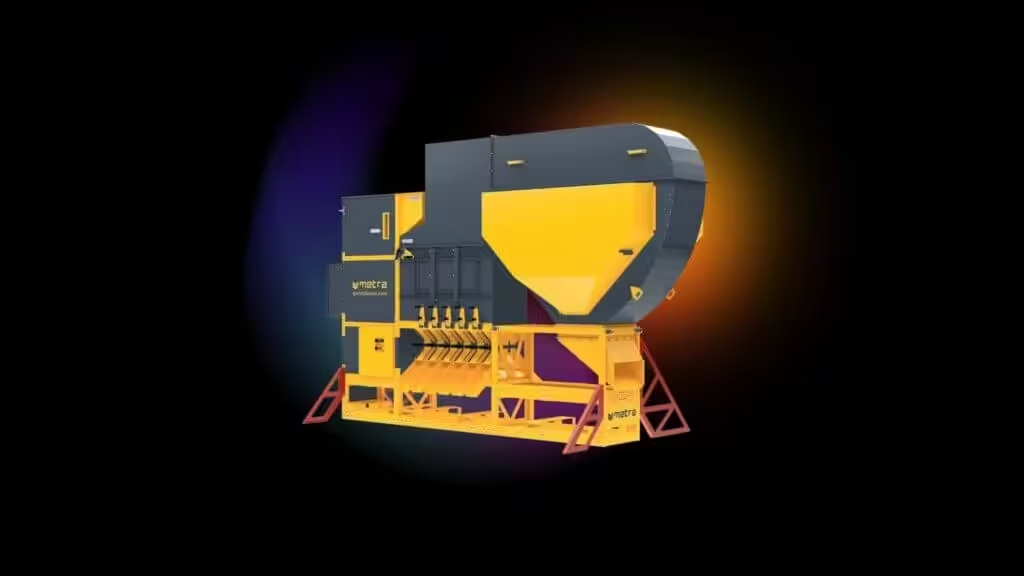

Modern agribusiness constantly faces a challenge: not only how to grow a large harvest but also how to deliver it to market in the best quality. Grain price on both domestic and international markets directly depends on moisture content, nutrient preservation, and overall appearance. That is why drying is a critically important stage of post-harvest processing. While traditional dryers are now considered outdated due to high costs and risks of spoilage, aerodynamic technologies from Metra represent a fundamentally new level of efficiency and profitability.

Operating Principle and Differences from Traditional Methods

Traditional dryers use the method of direct air heating, which passes through the grain and gradually evaporates moisture. This process often causes issues: overdrying, overheating, and cracks in the grain. Such defects reduce quality and, consequently, the selling price.

Aerodynamic technology applies an accelerated airflow that evenly surrounds the grain mass, lowering moisture without extreme temperatures. This method minimizes mechanical damage and allows processing of a wide range of crops.

Energy Efficiency—an Unmatched Source of Savings

Conventional dryers mostly operate on gas or diesel, leading to significant expenses. For large harvest volumes, fuel costs can reach tens of thousands of dollars per season. In addition, they contain numerous mechanical parts—burners, blades, ventilation systems—that require frequent repairs and replacements.

In contrast, aerodynamic dryers:

- consume 2–3 times less electricity,

- require no gas or liquid fuel,

- have no complex units, which minimizes repair costs.

Financially, this means an agricultural enterprise can reduce the cost of drying one bushel of grain several times over. When processing thousands of bushels, the savings become substantial, turning into additional profit or a reserve for reinvestment.

Grain Quality and Market Price

Another major advantage of aerodynamic drying is the preservation of grain structure and nutrients. While traditional systems often lead to brittleness or gluten damage, in modern units, the grain remains “alive”.

The financial effect is twofold:

- Grain does not downgrade in class, allowing it to be sold at higher prices.

- Seed material retains germination capacity, making it possible to sell at premium rates.

- The output of higher-grade grain provides farmers with a direct opportunity to earn more, even without increasing yield.

Durability and Fast Payback of Equipment

Traditional dryers demand ongoing spending on fuel and maintenance, which cuts into profits. Aerodynamic units are designed for long-term operation—over 25–30 years with proper care. The absence of moving parts reduces breakdown risks, and the simple construction makes them easy to use even for smaller farms.

Thanks to low operating costs and the high quality of the final product, such machines pay for themselves several times faster than classical alternatives.

Entering International Markets Through Modern Technology

Grain dried in aerodynamic units meets international standards for moisture, cleanliness, and safety. This provides producers with clear advantages:

- easier contract negotiations with European and Asian traders,

- access to premium market segments,

- minimized risk of rejection during product certification.

In other words, investing in aerodynamic dryers means not only cost savings but also the opportunity to achieve higher margins and attract new foreign partners.

Why Consider This Option?

Aerodynamic grain drying technology changes the approach to post-harvest processing. It provides agribusiness with:

- significant reductions in maintenance costs,

- improved grain quality,

- preservation of a larger share of the harvest without losses,

- fast return on investment,

- long-term financial benefits.

Compared to traditional methods used by producers in the past, aerodynamic grain drying stands out as a strategic solution that allows your company to enter new markets, generate additional profit, and actively grow.